Penetrant Testing, referred to as PT in the industry, is the earliest non-destructive testing method for industrial nondestructive testing. Because Penetrant Testing is simple and easy to operate, it has wide applications in various fields of modern industry.

Penetrant flaw detection is a non-destructive test method for inspecting surface opening defects based on the principle of capillary action. It is almost independent of the shape, size, structure, chemical composition and orientation of the parts to be inspected. It can be widely applied to the quality inspection of various processing techniques such as forgings, castings and welded parts, as well as metals, ceramics, glass and plastics. Quality inspection of parts made of various materials such as powder metallurgy.

Materials to be inspected include metals (steel, aluminum alloys, magnesium alloys, copper alloys, heat resistant alloys, etc.) and non-metals (plastics, ceramics, etc.)

Industrial products may produce surface cracks with a width of a few microns on the surface during manufacturing and operation. Fracture mechanics studies have shown that under severe operating conditions, these microcracks are the source of cracks that cause equipment damage.

Features Summary for Penetrant Testing:

- Not subject to material structure and chemical composition, suitable for non-ferrous metals, ferrous metals, plastics, ceramics and glass.

- High sensitivity. Cracks having a width of 0.5 μm, a depth of 10 μm, and a length of 1 mm can be clearly displayed.

- Simple equipment, easy to carry, low detection cost, suitable for field work

- Not suitable for inspection of workpieces made of porous or loose materials or workpieces with rough surfaces.

- Only surface opening defects can be detected

- Only the surface distribution of the defect can be detected, and it cannot be quantified.

Classification of Penetrant Testing Methods:

According to the dye component contained in the permeate, it can be divided into three major methods:

- Fluorescent Penetrant Testing

- Coloring Penetrant Testing

- Coloring Fluorescent Penetrant Testing

The permeate contains a fluorescent substance, and the defect image is a fluorescent method that excites fluorescence under ultraviolet light. The permeate contains a colored dye, and the defective image is colored by white light or sunlight. In addition, there is a class of penetrants that use special dyes that can both illuminate under visible light and fluoresce under ultraviolet light.

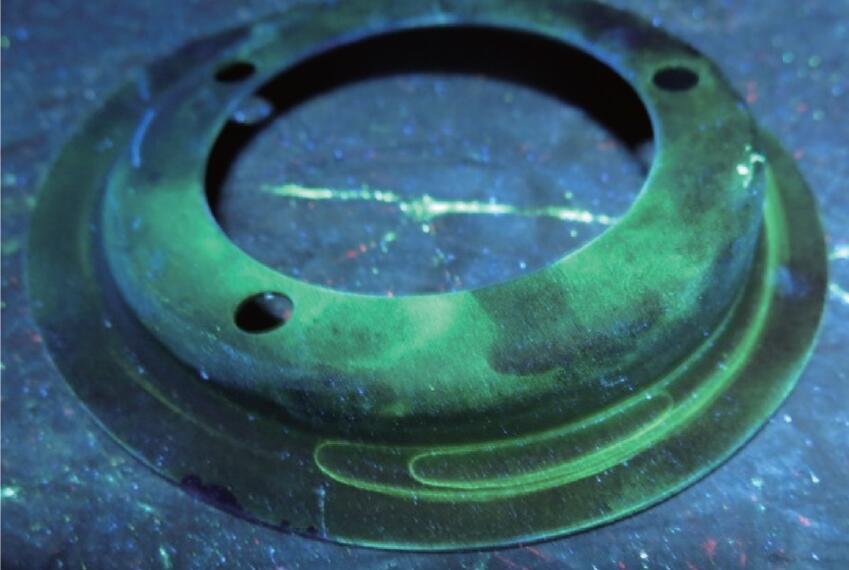

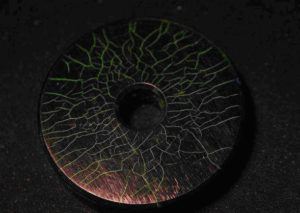

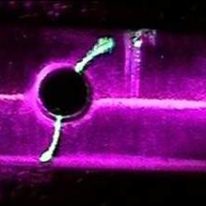

Typical fluorescent penetrant testing defect is as follows:

Micro-cracks that are invisible to the naked eye are examined by fluorescence permeation. Under the irradiation of ultraviolet light, the yellow-green fluorescence is particularly eye-catching, as shown in the picture above.

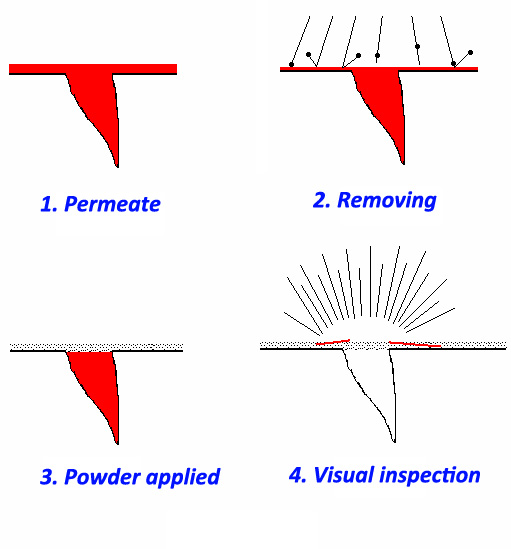

Penetrant Testing Principle:

It is a detection technology based on the principle of capillary action. It is mainly used to detect surface opening defects of non-porous metal or non-metal parts.

- A liquid dye is applied to the surface of the part and allowed time to seep into surface breaking defects.

- The excess liquid is removed from the surface of the part.

- A developer (powder) is applied to pull the trapped penetrant out the defect and spread it on the surface where it can be seen.

- Visual inspection is the final step in the process. The penetrant used is often loaded with a fluorescent dye and the inspection is done under UV light to increase test sensitivity.

Penetrant Testing Steps:

Other Things that Penetrant Testing need to pay attention to:

- The penetrant component has certain corrosiveness to the workpiece to be inspected, and the presence of trace elements such as sulfur and sodium must be strictly controlled.

- The organic solvent used in the penetrant is volatile, and the industrial dye is toxic to the human body, and attention must be paid to inhalation protection.