NDT (Non-destructive Testing) is also called NDE (Non-destructive Examination), NDI (Non-destructive Inspection), or NDE (Non-destructive Evaluation). It is to confirm whether there are conditions or structural discontinuities that affect the performance of the object, and various inspection, testing and evaluation methods are carried out without changing the state and properties of the object.

There are many non-destructive testing methods. According to the investigation and analysis by the National Aeronautics and Space Administration of the United States, it is believed that it can be divided into six categories and about 70 kinds.

Common non-destructive testing methods that are used in practical applications:

- Ultrasonic Testing (UT)

- Radiographic Testing (RT)

- Magnetic Particle Testing (MT)

- Penetrant Testing (PT)

- Eddy Current Testing (ET)

Unconventional non-destructive testing methods include:

- Acoustic Emission (AE)

- Leak Testing (UT)

- Optical Holography

- Infrared Thermograph

- Microwave Testing

Some brief introduction about the major five Non-destructive Testing Methods:

1. What is Ultrasonic Testing (UT)?

When the ultrasonic wave propagates in the material to be tested, the acoustic properties of the material and the changes in the internal structure have a certain influence on the propagation of the ultrasonic wave. The technique of understanding the material properties and structural changes by detecting the degree and condition of the ultrasonic wave is called ultrasonic testing.

2. What is r Radiographic Testing (RT)?

A technique for detecting the discontinuity of internal structure by using rays (X-rays, gamma rays, neutron rays, etc.) when passing through a material or a workpiece is called ray detection. The rays passing through the material or the workpiece are different in sensitivity to the X-ray film due to the difference in strength, thereby generating an internal discontinuous image.

3. What is Magnetic Particle Testing (MT)?

Magnetic particle testing is a non-destructive testing method for finding discontinuities in the surface and near surface of a test piece using magnetic flux leakage and a suitable test medium.

4. What is Penetrant Testing (PT)?

The capillary is permeated into the open defect of the surface of the solid material by capillary action of the liquid. The infiltrated permeate is then aspirated to the surface by a developer to reveal the presence of defects. This non-destructive testing method is called penetration testing.

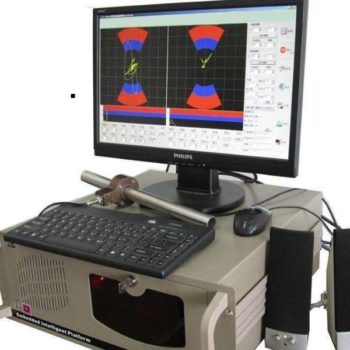

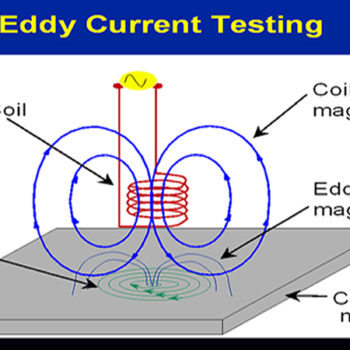

5. What is e Eddy Current Testing (ET)?

A non-destructive testing method that analyzes the internal quality of a workpiece using a eddy current induced by a ferromagnetic coil in a workpiece is called eddy current testing.